Premix Processing Solutions

Partnering with KSE Group

Premix processing plays a vital role in the minerals industry, enabling the creation of customized mineral blends. At KSE Group, we specialize in premix processing equipment using ALFRA technology to accurately mix and process minerals. Our solutions ensure consistent particle sizes and precise compositions. Partnering with us means accessing tailored solutions for premix processing, whether you're enhancing current systems, developing new blends, or seeking cost-efficiency. With a commitment to high-quality premix processing equipment, KSE reinforces its reputation as a trusted partner in the minerals industry.

Premix Plant Equipment

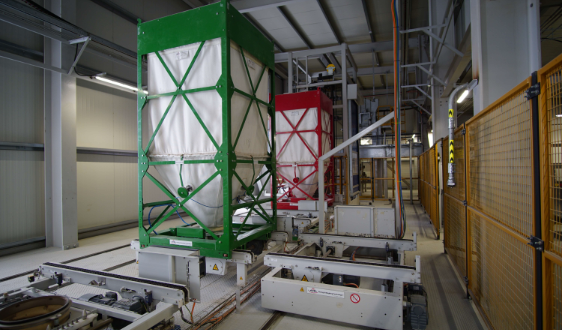

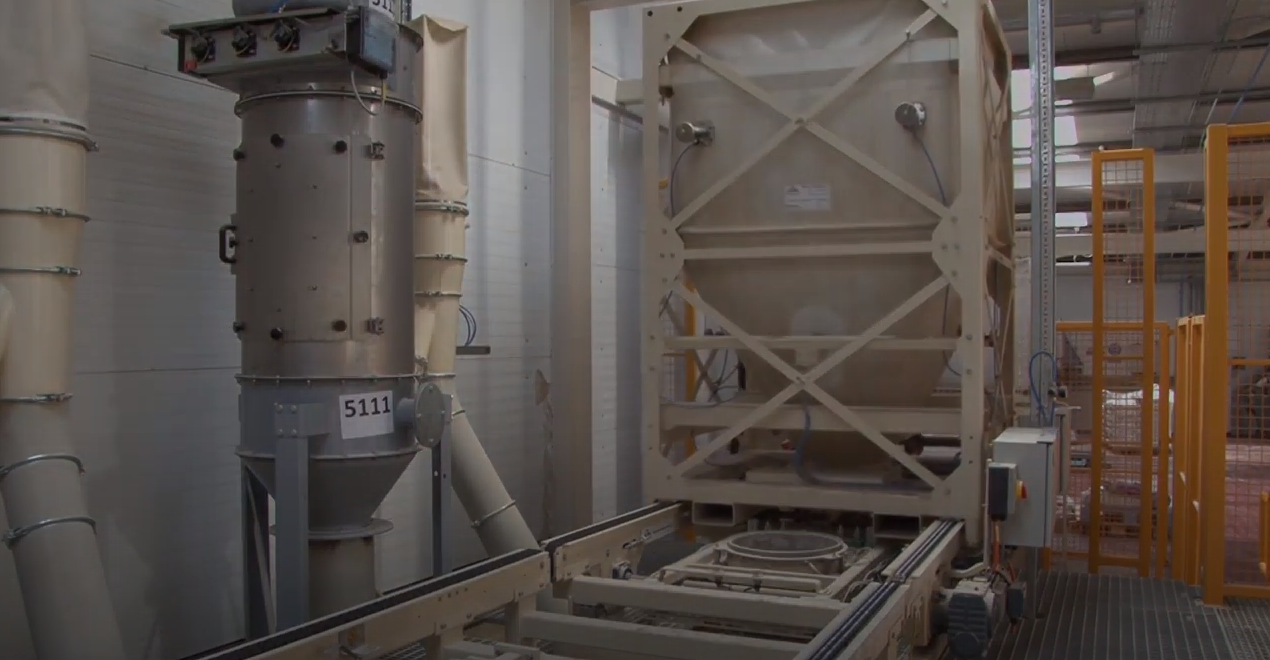

ALFRA | Automatic Container Transfer (ACT)

Looking for flexible premix plant equipment that minimizes contamination and maximizes safety? The ALFRA container transport system provides a fully automated solution for handling ingredients in animal feed premix equipment companies and mineral feed operations. Designed to manage recipes with varying inclusion rates and diverse ingredients, this robust, energy-efficient system is dust-free and highly adaptable. To ensure top-tier product safety and quality, ALFRA incorporates advanced features such as RFID coding, Tracking & Tracing, and check weighers—making it indispensable for high-performance premix processing.

Provimi Cargill

Jack O'Connor

"We chose the ACT because traditional processes are continuous, and our needs are more batch-driven. With up to 400 products and daily requirements of 20 to 50, the ACT system allows us to efficiently manage pre-mix batches. This system supports individual batches ranging from 2 to 4 tons, offering flexibility and speed.

One significant advantage is its space-saving design, requiring only one lift to move materials vertically between floors and transport finished products. The lift aligns perfectly with the stringent Cargill safety standards. Working with KSE ensured all elements met these standards, making maintenance and safe access seamless."

Mineral process equipment have strict requirements

Producing your own new mix mineral blends and feed minerals comes with challenges. Even small mistakes can result in costly errors. Animal feed premix companies require systems with high accuracy and minimal contamination to handle three times the number of ingredients compared to regular feed.

The ALFRA dosing and weighing equipment is designed for precision in premix formulation. This automated, container-based system ensures seamless throughput, reduces contamination risks, and meets the rigorous demands of premix processing. With advanced technology and self-learning software, it provides a robust solution for premix formulation, helping companies produce high-quality premixes consistently.

Mineral process equipment by KSE Group

Meeting High-Quality Standards

KSE Group offers advanced solutions for premix formulation and mineral processing, tailored to your production requirements. Our systems are designed to:

- Prevent cross-contamination.

- Facilitate the production of smaller, specialized batches.

- Map the entire production process effectively.

Our expertise ensures compliance with the highest industry standards, helping you produce premixes with efficiency and precision. Whether you're dealing with definition of premix or navigating production challenges, KSE provides innovative technologies for success.

How can we help?

Contact our team

Want to find out how KSE can solve problems specific to your business? Our team is happy to answer all your questions.

Fill out the form and we’ll be in touch as soon as possible.

Services within this industry

How we can help you optimize

KSE is a leading global supplier for optimizing production processes. We create flexible processing solutions that enable a responsive production process, for conventional as well as complex projects.